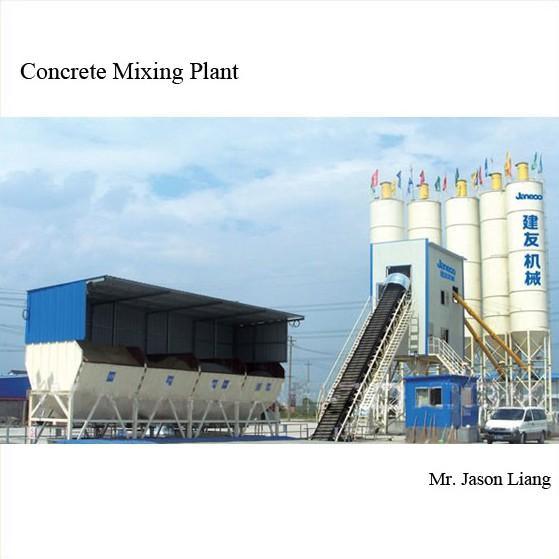

Janeoo Hzs60q Concrete Mixing Plant

- Price can be negotiated

- 1 Unit

- 45 Unit

- 18 days

Product Description

JANEOO HZS60Q concrete mixing plant

Feature of Q Series Economical Containerized Concrete Mixing Plant

1. With the loader to feed the material;

2. The screw conveyor is from WAW company;

3. The strap machine adopts standard section design (12m long each) to meet the transport requirements, and it is convenient to adjust the length of inclined belt conveyor;

4. With the electronic scale measurement, which is of high precision and small errors;

5. In addition to HZS60Q, the mixing console adopts the Italian BonFIGLIOLI shaft-mounted reducer;

6. HZS100Q and HZS150Q are equipped with the high quality TOLEDO sensor;

7. HZS100Q and HZS150Q use Japanese SMC solenoid valve;

8. HZS100Q and HZS150Q ADOPT Italian WAW butterfly valve products;

9. The main electrical components are all from Schneider Electric Company;

10. Can add a cold dryer (to be ordered separately) to ensure that the gas system reliable operation in winter;

11. Equipped with dust collector at the top of the powder silo and rain cover on the strap conveying machine to prevent dust from blowing;

12. The control system has the functions of screen displaying and drop automatically correcting, etc. It provides manual operation to control mixing procedure by manually and automatically. It also provides printing system and monitor system.

Application of Q Series Economical Containerized Concrete Mixing Plant

This important concrete equipment is popularly used in ready-mix concrete plants, which are small occupation area and small invested, as well as in the mobile construction site.

Feature of Q Series Economical Containerized Concrete Mixing Plant

1. With the loader to feed the material;

2. The screw conveyor is from WAW company;

3. The strap machine adopts standard section design (12m long each) to meet the transport requirements, and it is convenient to adjust the length of inclined belt conveyor;

4. With the electronic scale measurement, which is of high precision and small errors;

5. In addition to HZS60Q, the mixing console adopts the Italian BonFIGLIOLI shaft-mounted reducer;

6. HZS100Q and HZS150Q are equipped with the high quality TOLEDO sensor;

7. HZS100Q and HZS150Q use Japanese SMC solenoid valve;

8. HZS100Q and HZS150Q ADOPT Italian WAW butterfly valve products;

9. The main electrical components are all from Schneider Electric Company;

10. Can add a cold dryer (to be ordered separately) to ensure that the gas system reliable operation in winter;

11. Equipped with dust collector at the top of the powder silo and rain cover on the strap conveying machine to prevent dust from blowing;

12. The control system has the functions of screen displaying and drop automatically correcting, etc. It provides manual operation to control mixing procedure by manually and automatically. It also provides printing system and monitor system.

Application of Q Series Economical Containerized Concrete Mixing Plant

This important concrete equipment is popularly used in ready-mix concrete plants, which are small occupation area and small invested, as well as in the mobile construction site.

| Model | HZS60Q |

| Theoretical productivity | 60m 3 /h |

| Mixer | JS1000C |

| Discharge height | 3.8m |

| Aggregate weighing accuracy | ±2% |

| Cement weighing accuracy | ±1% |

| Fly ash weighing accuracy | ±1% |

| Additives weighing accuracy | ±1% |

| Water weighing accuracy | ±1% |

| Aggregate conveying speed | 230m 3 /h |

| Aggregate bin capacity | 3x12m 3 |

| Cement silo | SNC100F |

| Powder additive bin | SNC100F |

| Cement screw conveyor | Φ219x9m |

| Powder additive screw conveyor | Φ219x9m |

| Total powder | 80kw (not include silo and screw conveyor) |

| Automatic cycle | 60s |

Product Images

/

/