3 Axle Aluminium Alloy Bulk Cement

- USD 23000.28 /Unit

- 1 Unit

- 97 Unit

- 25 days

Product Description

product parameter(volume different the parameter will change)

| volume | 40M3 |

| payload | 45ton |

| tare weight | 7000kg |

| axle | 3x13ton/14ton/16ton/20tonbrand can be opentional |

| suspension | mechanical suspension/air suspension/american type/germany type can be opentional |

| tire | 11R22.5/12R22.5/11.00R20/12.00R20brand can be opentional |

| wheel rim | 8.25/9.0/8.0/8.5 |

| kingpin | 2"/3.5" |

| Ibeam | aluminium 5183 material |

| landing gear | jost c200 /fuwatwo speed 28ton |

| tankbody | 6mm thickness |

| end plate | 7mm thickness |

| spare tire carrier | one |

| engine | weichai(tianhe/huafeng) can be opentional |

| air compressor | bohai 12m3/sansen/keda/taike can be opentional |

| electricity wiring | 6 core wiring;24v or 12v ;LED lamp; |

| brake system | wabco relay valve;drum brake;t30/30 brake chamber |

| paiting | complete chassis sand blasting;electrophoresis coating;1 coat of anticorrosive prime; 2coats of final paiting |

| tank type | v type or stereoscopic as customer requirment |

| accessories | brake shoe;spare tire cranking;shaft head wrench;jack 50ton;tire bolt;lamp |

BRIEF DEscriptION

the normal produce process is very important.it can be influence the quality-durable years of the product .even the customer confidence to our product.

3.NORMAL PROCEDURE

1)cutting

use the plasma cutting machine cut the steel to little parts use for suitable welding and splicing

2)welding

after steel cutting process the next step is welding .this process the main work is beam welding .the top plate-bottom plate and the

middleplatewillbe welding together .this process will be use submerged arc welding process.this type of welding is very

special .its exclusively used in Ibeam welding .after this welding process other parts of the trailer will be use different welding way

for different steel-argon arc welding-electric arc welding-manual welding-gas welding and so on

3)blasting

this process is use for the first step of surface cleanness-stress relief-derusting before paiting .

4)electrophoresis coating

this process use for more detail surface cleanness

5)epoxy zinc primer spray coating

this process is the lasting one before paiting .after this process the trailer an be paiting

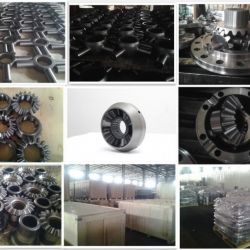

6)assembly

after all the process we have mationed .the last procedure of the trailer is assembly.this process all the parts will be assemly .it including tire-wheel rim-king pin-landing gear-suspension-spring leaf -brake chamber-air wiring-electricity wiring-brake system and so on

7)packing

The last process is packing .all the trailer use different packing way as customer requirment.after packing the trailer can be on the way to the customer

Product Images

/

/