Cheaper 60~80t/H Asphalt Mixing Plant (LB1000)

- Price can be negotiated

- 1 Unit

- 93 Unit

- 19 days

Product Description

Cheaper 60~80t/h Asphalt Mixing Plant(LB1000)

We are the specialized asphalt mixing plant supplier in China. With high reputation and competitive price. Welcome your inquiry at any time. Email me or call me directly if any question at any time.

Attd: Haitao Yan

Tel: +86-18653113471

| LB1000 Asphalt Mixing Plant | ||||

| The main parameters | ||||

| Model: LB1000 | ||||

| TYPE: Modular Design, Easy assembly, Easily disintegrated, Intermittent type, All Computer Operator | ||||

| Yield: 60~80t/h | ||||

| Mixing capacity: 1000kg/· | ||||

| Voltage: 380V/220V 50Hz | ||||

| Operation: Auto / Semi / Manual / Full computer control | ||||

| Capacity: ~230kw | ||||

| Main technical specifications | ||||

| 1. Equipments supplying Cold aggregate | ||||

| Cold material hopper (setting separate network at hatch opening) | A. 8m3 (paper-cover) | |||

| B. 9.5 m3 (Stowage) | ||||

| C. 4 set | ||||

| Ingredients Conveyor (electromagnetic speed-regulator) | A. Type: Belt-type feeder | |||

| B. Capacity: 0~50t/h | ||||

| C. Belt: Width: 500mm | ||||

| D. Quantity: 4set | ||||

| E. Geared Motors: BWD2-17-3kw | ||||

| Vibration device | A. Model: ZF18-50 | |||

| B. Quantity: 1 set in the sand silo | ||||

| Aggregate Conveyor | A. Type: three-point bracket-style groove shape frame | |||

| B. Capacity: 90t/h | ||||

| C. Belt: Width: 65mm | ||||

| D. Geared Motors: BWD3-17-4kw | ||||

| Feed conveyor | A. Type: three-point bracket-style groove shape frame | |||

| B. Capacity: 90t/h | ||||

| C. Belt: Width: 650mm | ||||

| D. Geared Motors: BWD3-17-4kw | ||||

| 2. Aggregate Drying System | ||||

| Drying drum | A. Type: tilt, rotary cylinder-type, counter-flow-packed by heating stainless steel plate | |||

| B. Productivity: Moisture 3%, When the discharge temperature of 150 ºC:80t/h;Moisture 5%, When the discharge temperature of 150 ºC:60t/h | ||||

| C. Drum Specifications:φ1540mmx6500mm | ||||

| D. Geared Motors: BWY4-29-5.5kw×4 | ||||

| E. Drivers: Friction-driven | ||||

| F. Temperature measuring probe: located in a feed box exit-control mill delivery of Charging Capacity according to temperature | ||||

| Coal pulverizer | A. Type: FD-700 | |||

| B. Productivity: 22kw | ||||

| C. Feeding power 3kw-electromagnetic speed-regulator | ||||

| Air blower | A. Model: Y4-72-5A | |||

| B. Productivity: 15kw-2P | ||||

| 3. Hot aggregate elevator | ||||

| A. Model: Vertical,Double-ring, Bucket, Gravity-dumping | ||||

| B. Productivity: 90t/h | ||||

| C. Geared Motors: BWD4-17-11kw | ||||

| 4. Aggregate Screening Equipment-- vibrating screen | ||||

| A. Model: Two-story Four sections Tilting, Screen using High-strength manganese steel material | ||||

| B. Productivity: 90t/h | ||||

| C. Motors: 5.5kw×4P×2SET | ||||

| D. Shell Size: 1410mm×3670mm×960mm | ||||

| E. Screen Size Configuration-square hole size-Shanghai Dunpai Factory Configuration: 5×5; 10×10; 15×15; 26.5×26.5 If need a special specification, please declare when order | ||||

| F. Damping device is set at the Junction with the host frame | ||||

| 5. hot silo | ||||

| A. Model: 4 silo with flash gate and Waste port | ||||

| B. Total capacity: 10.5m3 | ||||

| C. Set a material level sensor can detect position in the silo | ||||

| D. 1. Hot silos discharge door, using the latest design, 2. Double cylinder: twice acts, 3 First rough measurement, precision after 4 Improve the measurement accuracy of stone | ||||

| 6. Measuring System | ||||

| Measuring of aggregate, asphalt, and powder all use three-point sensor , which make the signal entry the electronic measure and processed by computer, digital display Weight, automatic amendment to motion compensation (have tracking function to deviation) | ||||

| Aggregate measuring | Weighing range: 1kg~2000kg | |||

| Hopper volume: 1.4m3 | ||||

| Asphalt Weighing | Weighing range: 0.1kg~300kg | |||

| Hopper volume: 0.15m3 | ||||

| Powder measuring | Weighing range:: 0.1kg~300kg | |||

| Hopper volume: 0.25m3 | ||||

| Transmission device: Using discharge device and screw conveyor | ||||

| 7. Mixing System | ||||

| A. Model: Twin-shaft, intermittent forced mixing | ||||

| B. Capacity: 1000kg/· | ||||

| C. Geared Motor: BWD6-17-22kw×2SET | ||||

| D. Material: liner board and vane are made of High-chromium alloy cast iron,vane arm is made of High-chromium alloy cast steel | ||||

| 8. Powder feed system | ||||

| Slag hoist: 2--- requiring moisture content of less than 2% | ||||

| A. Model: Vertical double chain bucket, gravity unloading | ||||

| B. Capacity: 25t/h | ||||

| C. Geared Motors: BWD3-17-4kw | ||||

| D. Quantity: 1SET | ||||

| 9. Pneumatic equipment | ||||

| A. Model: Piston type, air-cooled | ||||

| B. Displacement: 1m3/min | ||||

| C. Pressure: 0.8Mpa | ||||

| D. Productivity: 7.5kw×4P | ||||

| E. Quantity: 1SET | ||||

| 10. Cyclone Dust (the first step to dust) | ||||

| A. Model: double barreled Cyclone Dust | ||||

| B. Size: φ1100mmx3060mm | ||||

| C. Productivity: >80% | ||||

| 11. Bag Filter (the second step) | ||||

| A. Model: impulse type | ||||

| B. specification: Bag quantity:360 | ||||

| C. Filter area: 360 | ||||

| D. Productivity: 99.5% | ||||

| E. H=7.5m | ||||

| 12. Fan | ||||

| A. Model: Y5-47-9C | ||||

| B. Air volume: 19640-36140m3/h | ||||

| C. Air pressure: 3156-2156mmH2O | ||||

| D. Motor type: Y225S-4,N=37kw | ||||

| E. Quantity: 1SET | ||||

| 13. All closed computer room | ||||

| A. Size: 4000mmx1900mmx2700mm | ||||

| B. Equipped with heating and cooling air-conditioning | ||||

| 14. Equipped with heating and cooling air-conditioning | ||||

| 14.1 Automatic Console by computer | ||||

| A. Model: Piano-style,all closed | ||||

| B. Operating temperature: 5ºC~35ºC | ||||

| C. Working humidity: 20%~70% | ||||

| D. Control system function: Can switch among manual, semi-automatic and fully automatic computer control, arbitrarily. | ||||

| E. The main input and output function | ||||

| 1). Enter a variety of mixing Gradation | ||||

| 2). Automatically adjust and accurately measure gradation are based on the input requirements | ||||

| 3). To collect feedback signal from various sensors and adjust the parts in time | ||||

| 4). Display discharge, weighing information and show the output and temperature. | ||||

| 5). Persist data in five years | ||||

| 6). View by a machine dynamic simulation Graph on the color monitor | ||||

| 14.2 Electric circuit: You configure under the guidance of the manufacturer | ||||

| A. All to use VV Cable | ||||

| B. Square: connect the control room with every segment of the mixing machine | ||||

| 14.3 Printer Features | ||||

| A. Print the time, product temperature and the actual mix gradation | ||||

| B. View and print the daily production data, very convenient and direct to know the produce | ||||

| C. Operation temperature: 5ºC~35ºC | ||||

| D. Working humidity: 20%~70% | ||||

| 15. Asphalt tank with heating device | ||||

| 5 0 tons of heating cans: 1 | ||||

| 16. Paint | ||||

| A. Main color: blue. Cleaning system color: silver Others: orange | ||||

| B. If require other colors, please tell when ordering | ||||

We are the specialized asphalt mixing plant supplier in China. With high reputation and competitive price. Welcome your inquiry at any time. Email me or call me directly if any question at any time.

Attd: Haitao Yan

Tel: +86-18653113471

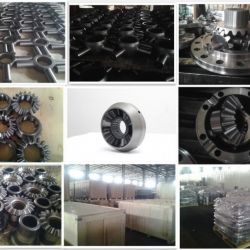

Product Images

/

/